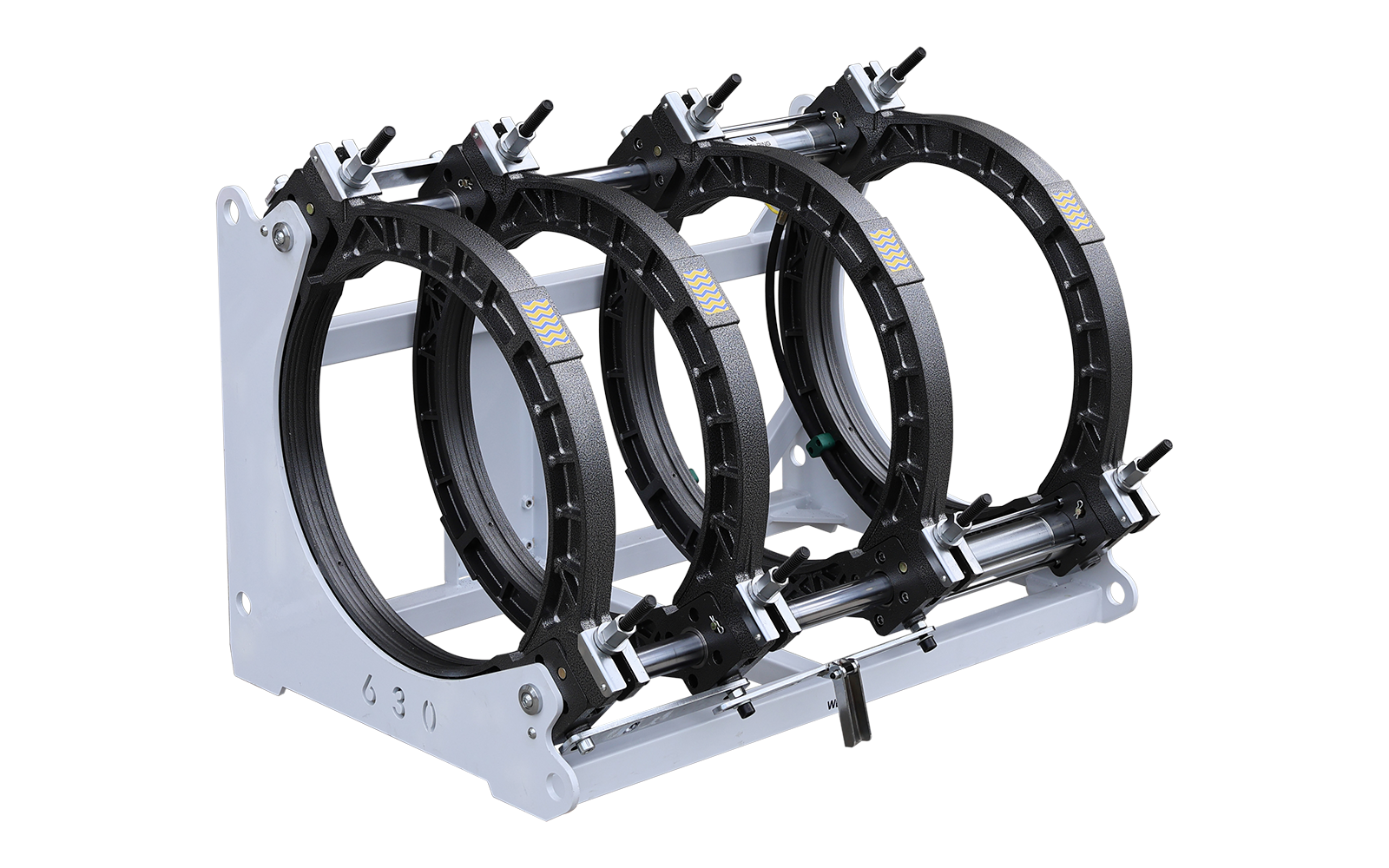

Wp630A PRO

WELPING

| Availability: | |

|---|---|

| Quantity: | |

The High-End Series WP630A PRO butt welding machine is a mechanical butt fusion welder for joining various types of plastic pipe including HDPE,PP,PB and PVDF.

The Butt Fusion Machine is designed to butt fuse pipe sizes 315mm to 630mm. It is easy to operate and incorporates a state-of-the-art heating plate, 4 jaws machine body, electric facer, and storage stand.

| Model NO. | WP630A Pro | Control | Semi-Automatic |

| Frequency Range | Low Frequency | Electric Current | AC |

| Type | Semi-Automatic | Weldable Material | HDPE/PP/PVDF |

| Rated Voltage | AC 380V, 50Hz, 1PH | Hydraulic | Enclosure Housing |

| Certificate | CE, SGS | Warranty | 12 Months |

| Rated Power | 10.1kW | Heating Plate | 7.5kW |

| Trimmer | 1.5kW | Hydraulic Unit | 1.1kW |

| Pressure Range | 0-8Mpa | Transport Package | Plywood Cases |

| Total Volume | 2.29cbm | Gross Weight | 540kg |

| HS Code | 8515809090 | Production Capacity | 20000pieces/Year |

· Complete reinforced welded steel structure, strong, free of distortion

· Aluminum strengthened clamping part

· 4 upper rings are equipped with anti - friction pads to protect the aluminum casting

· Qualified hydraulic cylinder with quick couplings, for easy installation

· Integrated hydraulic and electrical control. All - in - one control panel: hydraulic actuation, pressure setting, timing, electric info display, temperature setting

· Enclosure design, shielding splash and dirt and wheels, for easy transportation

· Built with Siemens or other well - known brand electronic components

· Cast aluminum body with built - in heating elements

· Anti - stick PEFT coating from Daikin

· Qualified aviation plug and heavy duty cable ensure operation safety

· Optional FX series heating plate with thicker casting and updated heating elements

· Full gear transmission structure, for steady and long - life performance

· Powerful copper - wiring motor

· Durable, double edges HSS blade

· Reinforced milling plate, withstands heavy - duty operation

· An Optional electric hoist is available for convenient installing and moving the facer and heating plate

· Connected to the rear mounting plate of the frame for overall stability

· Designed for quick installation and removal

The High-End Series WP630A PRO butt welding machine is a mechanical butt fusion welder for joining various types of plastic pipe including HDPE,PP,PB and PVDF.

The Butt Fusion Machine is designed to butt fuse pipe sizes 315mm to 630mm. It is easy to operate and incorporates a state-of-the-art heating plate, 4 jaws machine body, electric facer, and storage stand.

| Model NO. | WP630A Pro | Control | Semi-Automatic |

| Frequency Range | Low Frequency | Electric Current | AC |

| Type | Semi-Automatic | Weldable Material | HDPE/PP/PVDF |

| Rated Voltage | AC 380V, 50Hz, 1PH | Hydraulic | Enclosure Housing |

| Certificate | CE, SGS | Warranty | 12 Months |

| Rated Power | 10.1kW | Heating Plate | 7.5kW |

| Trimmer | 1.5kW | Hydraulic Unit | 1.1kW |

| Pressure Range | 0-8Mpa | Transport Package | Plywood Cases |

| Total Volume | 2.29cbm | Gross Weight | 540kg |

| HS Code | 8515809090 | Production Capacity | 20000pieces/Year |

· Complete reinforced welded steel structure, strong, free of distortion

· Aluminum strengthened clamping part

· 4 upper rings are equipped with anti - friction pads to protect the aluminum casting

· Qualified hydraulic cylinder with quick couplings, for easy installation

· Integrated hydraulic and electrical control. All - in - one control panel: hydraulic actuation, pressure setting, timing, electric info display, temperature setting

· Enclosure design, shielding splash and dirt and wheels, for easy transportation

· Built with Siemens or other well - known brand electronic components

· Cast aluminum body with built - in heating elements

· Anti - stick PEFT coating from Daikin

· Qualified aviation plug and heavy duty cable ensure operation safety

· Optional FX series heating plate with thicker casting and updated heating elements

· Full gear transmission structure, for steady and long - life performance

· Powerful copper - wiring motor

· Durable, double edges HSS blade

· Reinforced milling plate, withstands heavy - duty operation

· An Optional electric hoist is available for convenient installing and moving the facer and heating plate

· Connected to the rear mounting plate of the frame for overall stability

· Designed for quick installation and removal