Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

Hydraulic butt fusion machines are transforming pipe welding in 2025. Demand grows across water, gas, mining, and petrochemical projects. Choosing the right model ensures safety, efficiency, and sustainability. In this article, you will discover the top hydraulic butt fusion machines and brands shaping the market.

The global market for hydraulic butt fusion machines is expanding rapidly. In 2023, it was valued at about $1.2 billion and is projected to nearly double by 2032 (data needs verification). This growth comes from rising infrastructure projects and the need for durable pipelines in utilities. Industries see these machines as essential for leak-free, high-pressure joints. Demand is further supported by governments investing in water treatment, energy distribution, and sustainable urban systems.

B2B buyers view these machines as long-term investments. They help reduce repair costs, meet safety standards, and improve project timelines. For suppliers, the growth creates intense competition, pushing innovation and service quality higher.

Hydraulic butt fusion machines are the backbone of modern pipe installation. They play a vital role in water supply networks, irrigation systems, and wastewater treatment plants. Gas utilities use them to connect pipelines that transport fuel safely under pressure. In mining, the machines join heavy-duty HDPE pipes that withstand abrasive conditions. Petrochemical plants rely on them to handle complex piping systems where chemical resistance matters.

These machines also adapt to geothermal heating projects, supporting renewable energy use. Each application requires strong, seamless joints that can perform reliably for decades. By offering consistency and safety, they remain critical across diverse industries.

Technology is reshaping how hydraulic butt fusion machines operate in 2025. Many models now integrate automation to handle repetitive steps. This reduces human error and speeds up production. AI-driven controls learn from weld data, adjusting heat and pressure for optimal results. These smart features help operators ensure compliance and improve quality assurance.

Eco-friendly innovations are also emerging. Machines now use low-energy heating systems, cutting operational costs and emissions. Durable materials extend service life, minimizing waste and replacement needs. IoT-enabled data loggers allow managers to track welding performance in real time, creating opportunities for predictive maintenance.

The combination of automation, AI, and sustainability ensures companies achieve efficiency and meet regulatory standards. For contractors, this means faster project delivery without compromising safety.

Note: When choosing hydraulic butt fusion machines, prioritize models offering automation and data logging to stay competitive in large-scale projects.

Choosing the right machine begins with pipe size and material. Hydraulic butt fusion machines are designed for HDPE, PP, and PVDF pipes. Each material has unique heat response and pressure needs. For example, HDPE is widely used for water systems, while PVDF is chosen for chemical resistance. A machine that supports a broad pipe diameter range offers more flexibility for contractors. This compatibility helps avoid costly mistakes during large projects.

The strength of a welding machine comes from its pressure range and power output. Machines with higher pressure ensure strong joints for large-diameter pipes. Durability matters too, since these machines often work in harsh environments. Stainless steel frames and coated heating plates extend service life. Power ratings also influence performance; higher wattage heaters reduce fusion time. Contractors should balance power needs against energy efficiency to maximize ROI.

Selection Factor | Why It Matters | Example Use |

Pressure Range | Ensures weld strength | High-pressure gas lines |

Heater Power | Reduces fusion cycle | Mining pipelines |

Durability | Longer lifespan | Outdoor water systems |

Operators need machines that simplify tasks and reduce risks. Features like digital temperature controls, ergonomic handles, and automated trimming systems improve usability. Safety protections, such as emergency stops and stable clamping, prevent accidents. Machines that log welding parameters also help maintain quality assurance. By combining user-friendly controls with robust safety features, companies can protect workers and improve efficiency.

Even the best hydraulic butt fusion machines require reliable service. Strong after-sales support ensures minimal downtime during projects. A two-year warranty, common among leading brands, gives buyers confidence. Access to spare parts and technical training also adds long-term value. When comparing options, businesses should weigh not just upfront costs but also service quality and warranty coverage.

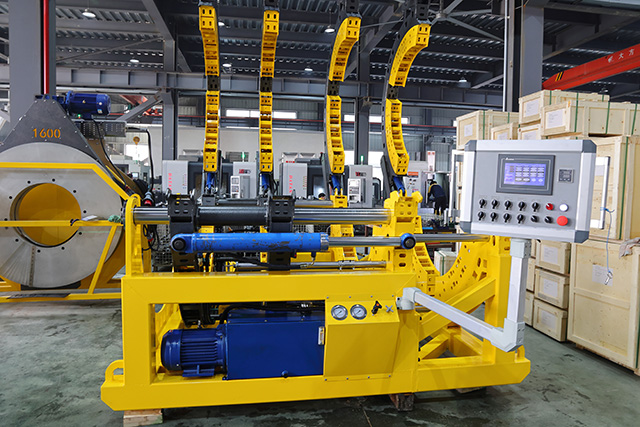

MM-Tech continues to lead in hydraulic butt fusion machines for heavy infrastructure projects. Its advanced models combine strong hydraulic systems with digital controls. Operators benefit from automated pressure adjustment and integrated data logging. The PEWeldBank system records every weld for traceability and compliance. Machines also feature non-stick heating plates for consistent results. MM-Tech is often chosen for gas and water pipeline projects where safety and accuracy are critical.

McElroy is a pioneer in butt fusion welding, offering rugged machines suited for both field and workshop use. The TracStar iSeries delivers automated fusion control, real-time parameter tracking, and remote operation through DataLogger® tablets. Its design ensures precise welds, even under challenging conditions. For smaller spaces, the Acrobat Series provides modular carriages and lightweight facers. These machines give contractors flexibility without compromising quality.

Ritmo specializes in delivering user-friendly machines with strong build quality. Its self-aligning system improves joint precision, while mobile frames make on-site handling easier. A highlight is Ritmo's focus on energy efficiency, reducing operational costs while meeting sustainability goals. Its models handle a wide range of pipe diameters and are valued in water transport and gas distribution. Italian engineering ensures durability, making Ritmo a trusted brand in global markets.

Worldpoly stands out for providing affordable yet reliable welding solutions. Its hydraulically operated machines are designed for both factory and field applications. Many models support optional add-ons like cranes or data loggers, giving buyers flexibility. Lightweight aluminum construction improves portability while maintaining strength. Worldpoly is especially popular in regions where infrastructure growth demands budget-friendly but dependable machines.

GF Piping Systems focuses on precision and operator convenience. Its machines feature touchscreen controls, multilingual menus, and handheld interfaces for remote use. Efficiency improvements include faster cooling times and reduced preparation steps. These features make GF machines highly attractive in industries requiring strict quality standards, such as pharmaceuticals and chemical processing. The brand's reputation for reliability makes it a strong choice for businesses seeking advanced technology.

Leo Engineers serves as a key player in Asia, offering durable and versatile hydraulic butt fusion machines. Its machines support a wide range of pipe diameters, from small field repairs to large industrial pipelines. Heavy-duty trimmers and digital heating control ensure accurate preparation and fusion. Localized production also makes them cost-effective for Indian and regional markets. Many contractors rely on Leo Engineers for municipal water projects and irrigation systems.

Beyond the major brands, several rising players are entering the market. Companies in China, Southeast Asia, and Africa are producing cost-competitive machines. While some lack the advanced automation of established brands, they appeal to buyers prioritizing price and availability. Emerging manufacturers are also experimenting with hybrid welding technologies and compact portable designs. This competition increases innovation and provides more options for global buyers.

The performance of hydraulic butt fusion machines largely depends on heater power and pressure capacity. Machines with higher wattage reduce fusion time, making them ideal for large-diameter projects. For instance, models offering up to 270℃±7℃ heating ensure consistent bonds even under tough site conditions. Balanced heating avoids uneven welds and lowers the risk of joint failure. Buyers should match power capacity to project size for maximum efficiency.

Not every project happens in a factory. Contractors working on pipelines in remote areas value portability. Lightweight frames, detachable modules, and wheeled carriages make transportation easier. Compact models like McElroy’s Acrobat Series are designed for confined spaces. Meanwhile, Worldpoly's aluminum-bodied machines balance portability and durability. Field-ready machines save time, especially when crews move between multiple job sites daily.

Digital features are transforming welding quality control. Machines that include data loggers automatically track temperature, pressure, and cycle times. This creates traceable records for compliance and audits. Some models also support IoT connectivity, allowing supervisors to monitor welds in real time. Digital integration reduces operator error and supports predictive maintenance. For industries such as oil and gas, data logging is no longer optional—it is essential.

While advanced features are attractive, cost remains a key factor. Worldpoly and Leo Engineers focus on affordability without sacrificing reliability. McElroy and GF Piping Systems command higher prices but deliver unmatched technology and global support. Businesses should weigh upfront investment against long-term ROI. Durable machines with strong after-sales service often reduce repair costs over time. In many cases, higher-priced models prove more economical across a machine’s lifespan.

The Asia-Pacific region leads demand for hydraulic butt fusion machines in 2025. Countries like China and India continue to expand pipelines for water supply, natural gas, and industrial use. Rapid urbanization fuels projects requiring reliable plastic piping networks. Many governments invest heavily in irrigation and wastewater systems, creating steady growth. Local manufacturers are also rising, offering cost-competitive options.

Large-scale infrastructure projects, such as smart cities and energy corridors, rely on durable welding solutions. Contractors in this region prefer machines that balance affordability and advanced features like automation. This trend makes Asia-Pacific the fastest-growing market globally.

Africa is experiencing strong growth due to investments in water treatment and gas distribution. Countries across Sub-Saharan Africa are expanding pipeline networks to improve access to clean water and energy. For these projects, hydraulic butt fusion machines provide cost-effective solutions. They ensure long-lasting joints, essential for rural and urban infrastructure.

Mining-heavy nations also adopt these machines to handle tough conditions. Demand is especially high for portable models that can be deployed in remote areas. International suppliers see Africa as a key growth market where durable, mid-priced machines gain strong traction.

In Europe and North America, demand is shaped by strict environmental standards. Buyers in these regions prioritize eco-friendly designs and digital integration. Machines that consume less energy, offer predictive maintenance, and log weld data are increasingly popular. This aligns with regulations targeting carbon reduction and worker safety.

European firms often adopt models with IoT features for compliance audits. North American contractors lean toward robust machines that perform reliably across extreme climates. High upfront costs are less of a barrier since lifecycle savings and compliance benefits outweigh the investment.

Modern hydraulic butt fusion machines are built to reduce energy consumption. Low-energy heating elements cut operating costs while lowering emissions. For example, optimized heating plates reach the required temperature faster, minimizing wasted electricity. These improvements help contractors meet sustainability targets and control budgets. In long-term projects, even a 10% reduction in energy use can translate into significant cost savings (needs verification).

Durability is a core element of sustainability. Machines designed with stainless steel parts and coated heating plates resist corrosion and wear. By lasting longer, they reduce the frequency of replacement, lowering both costs and waste. Fewer breakdowns also mean fewer disruptions to project schedules. Investing in durable machines allows businesses to extend lifecycle performance while reducing environmental impact.

Governments in Europe and North America enforce strict rules on energy efficiency and emissions. Using eco-friendly hydraulic butt fusion machines helps companies stay compliant with these regulations. Machines equipped with smart controls adjust power use automatically, preventing excess consumption. This compliance not only avoids penalties but also strengthens reputation with clients who value sustainability. Contractors using greener technology can also qualify for certain incentives or certifications.

The first step in selecting hydraulic butt fusion machines is aligning capacity with project requirements. Small-diameter water lines may only need compact machines, while large industrial pipelines demand high-pressure, high-power models. Overbuying wastes capital, but underpowered machines slow projects and risk weak welds. Buyers should review pipe size ranges, pressure ratings, and material compatibility before finalizing a purchase.

Many buyers make errors by focusing only on price or brand reputation. Ignoring key features such as data logging, portability, or after-sales support often leads to downtime. Another mistake is overlooking operator training needs. Even advanced machines fail to deliver if users are not properly trained. A structured evaluation process ensures the machine fits both technical and workforce requirements.

High-quality machines can appear expensive, but they often lower lifecycle costs. Durable parts, lower energy use, and reduced maintenance contribute to long-term savings. Machines that meet global compliance standards also reduce risks of penalties and project delays. Buyers should calculate ROI by comparing not just purchase price but also energy consumption, expected lifespan, and service availability.

Hydraulic butt fusion machines are essential for reliable pipelines in 2025. The right choice improves efficiency, safety, and long-term sustainability. Buyers should match project needs with machine capacity and features to avoid costly errors. Leading brands showcase how advanced design and digital tools transform performance. Companies like Welping deliver machines with durability and smart controls, helping projects achieve consistent quality and strong ROI.

A: Hydraulic butt fusion machines join HDPE, PP, or PVDF pipes for water, gas, and mining projects.

A: They ensure efficient, eco-friendly pipeline welding as infrastructure demand grows worldwide.

A: Match pipe size, material compatibility, pressure range, and durability to your project needs.

A: Costs vary, but higher-quality machines reduce maintenance, save energy, and deliver long-term ROI.