Views: 0 Author: Ruby Publish Time: 2025-11-04 Origin: Site

At Welping’s factory, rows of 630 heating plates are lined up neatly, awaiting final inspection and assembly. Each plate represents not only precision in manufacturing, but also Welping’s dedication to stable heating performance and long-term reliability in every butt fusion welding project.

The heating plate is the heart of every HDPE butt fusion machine. Its temperature accuracy directly determines the strength and smoothness of the welded joint. At Welping, each 630 mm heating plate undergoes strict machining, PTFE coating, and calibration to ensure temperature consistency within ±5 °C — delivering uniform fusion results in the field.

From aluminum casting and surface finishing to electrical testing and assembly, every step follows a standardized quality process. Large-scale synchronized production guarantees batch consistency and allows seamless integration with Welping’s hydraulic and frame systems, ensuring every component works perfectly together.

Each 630 heating plate leaving our production line is more than a product — it’s a reflection of Welping’s engineering discipline, our pursuit of efficiency, and our promise to customers worldwide for reliable, precise fusion equipment.

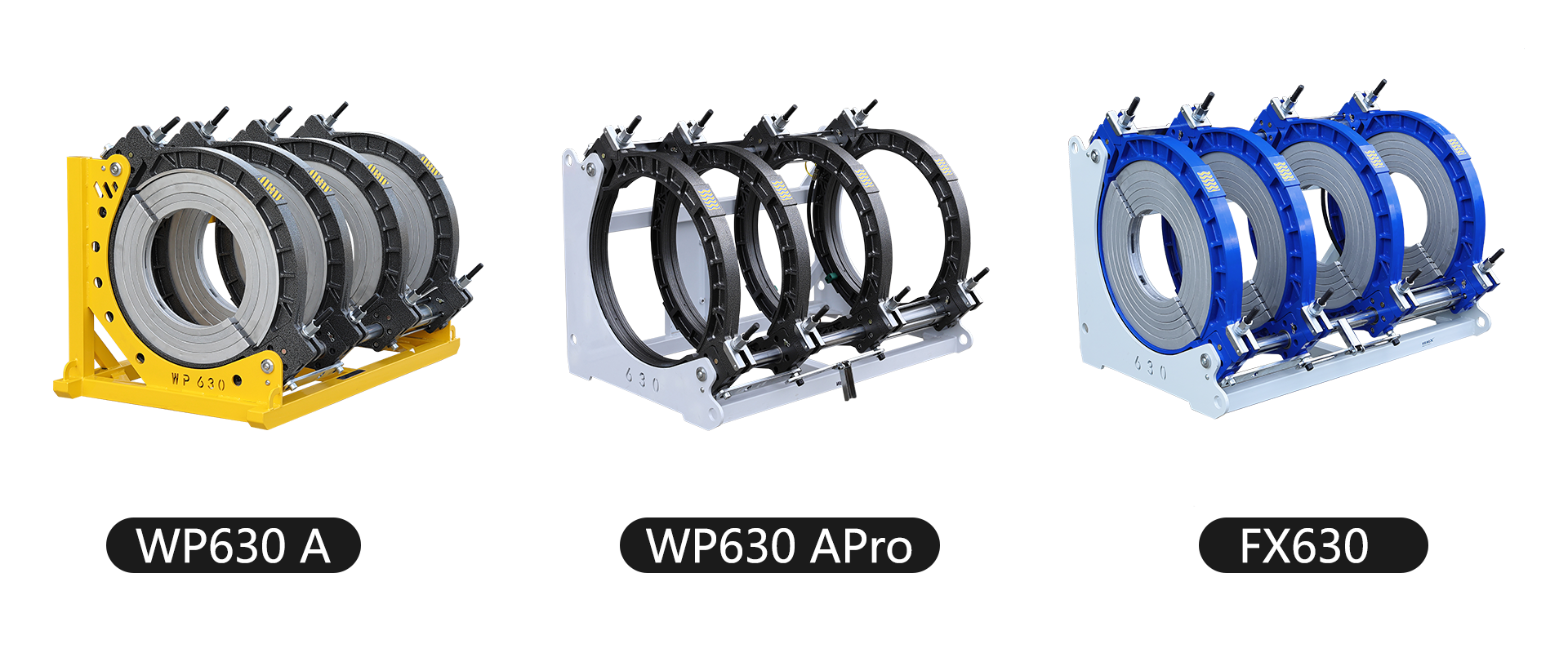

Welping’s 630 butt fusion machines are available in three distinctive series — the A Series (Flagship), A Pro Series (Upgraded), and FX Series (High-end).

Each is designed to meet different welding needs, from classic durability to advanced precision and intelligent control.

Customized solutions are also available to match specific project requirements.

If you’d like to learn more about our complete range of butt fusion welding machines, please click here.