Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

Choosing the right plastic welder depends on your project and skill. If you fix plastics in cars, boats, or factories, you need a tool that is precise and reliable. The Weldy HT1600 hot air welding gun is great for people who want steady results on hard jobs. This plastic welder works well for many tasks, like fixing car bumpers or making plastic tanks. Some plastic welders are better for small crafts or quick repairs. Others, like the Weldy HT1600, are good for big or factory jobs. You can pick the best plastic welder by knowing what each tool does well and what you need for your job.

Hot air welding guns like the Weldy HT1600 give you good control. You can change the heat. They feel comfortable to use. They work well for many plastic repair jobs. They are also good for making things with plastic.

Different plastic welders work best for different jobs. Extrusion welders are good for thick plastics. Ultrasonic welders are fast and work well on small parts. Chemical welders are quick and easy for simple fixes.

Practice and getting ready make your welds stronger. Always clean the surfaces first. Use rods that match your plastic. Test on scrap material before you start your real project.

Pick your plastic welder by thinking about your project size. Think about your skill level and how much money you want to spend. This helps you get the best results and value.

Safety is important. Wear gloves and eye protection. Work in places with fresh air. Follow the instructions to keep yourself and your work safe.

When you want a plastic welder, you will see many kinds. Each kind is best for certain jobs. Here is a short guide to help you know the main choices.

| Type | Main Features & Uses | Market Position (2024) |

|---|---|---|

| Hot Air Welding Gun | You can change the heat. It works for many jobs. It is used for lots of plastic welding work. | Many people use it for hand and semi-automatic jobs. |

| Soldering Iron | It has a hot metal tip. It is good for small fixes and electronics. | People use it a lot for hobbies and repairs. |

| Extrusion Welder | It melts plastic rods and pushes them out. It makes strong welds for thick plastic. | Used in big factories and on building sites. |

| Ultrasonic Welder | It uses sound waves. It is fast and neat. You do not need extra glue. | Most used in factories, especially for making things. |

| Chemical Welder | It uses special liquids to stick plastics together. | Good for quick fixes and crafts. |

You use a hot air welding gun for many plastic jobs. This tool blows hot air that you can control. You can fix plastic sheets, pipes, or car bumpers. The Weldy HT1600 is special because it gives pro results. You get steady heat and easy control. The handle is comfy to hold. Many workers pick this tool for hard jobs.

A soldering iron has a hot tip. You use it to melt small spots of plastic. This tool is good for toys, electronics, or tiny cracks. It is simple and easy to find. You might use it for fast fixes or fun projects.

An extrusion welder melts plastic rods and pushes them out. You use it for thick plastic or strong welds. It is best for tanks, pipes, or big plastic things. You often see it in factories or on building sites.

An ultrasonic welder joins plastics with sound waves. You do not need glue or rods. This tool is very fast and makes clean welds. You find it in car plants, electronics, and medical work. Many companies use it because it saves time and works well.

A chemical welder uses special liquids to join plastics. You brush or squeeze the liquid on the plastic. The surfaces melt a bit and stick. This tool is good for crafts, models, or small fixes. You can use it at home or in a shop for quick repairs.

Tip: Think about your project and what it is made of before you pick a plastic welder. Each kind is good for different things.

When you use a hot air welding gun, you direct a stream of hot air onto the plastic surfaces you want to join. You also feed a plastic rod, which should match the type of plastic you are working with. The heat gun has a heating element, an airflow guide, and a nozzle. You control the temperature and the speed of the air. As the hot air softens both the plastic and the rod, you press them together. This creates a strong weld. You need to move the heat gun smoothly and keep the right distance. Unlike other plastic welder tools, this method uses direct hot air and a filler rod. Other methods, like ultrasonic or laser welding, use sound or light instead of hot air. Traditional heat guns do not offer the same control or precision as a hot air welding gun.

You get many benefits when you choose a hot air welding gun for your plastic welder needs:

Adjustable temperature settings let you match the heat to different plastics.

The ergonomic handle makes long jobs easier on your hands.

Good nozzles help you heat the right spot every time.

You can use this plastic welder for many shapes and sizes.

The Weldy HT1600 stands out because it reaches up to 700°C. You can adjust the temperature with a simple knob. The tool is strong and built for tough jobs. It lasts longer than most traditional heat guns.

You save money because this plastic welder works for many projects.

You get strong, even welds if you clean and prepare your materials well.

Traditional heat guns often lack the fine control and durability you need for professional plastic welder tasks. The Weldy HT1600 gives you more power and better results than most traditional heat guns.

Note: A hot air welding gun is flexible and cost-effective. You can use it for repairs, crafts, or big jobs.

You should know the limits of a hot air welding gun before you start. This plastic welder works best for small repairs and thin materials. If you try to weld plastic thicker than 10mm, you may not get a strong bond. For thick plastics, you should use an extrusion plastic welder. You must match the rod to the plastic type. If you set the heat gun too hot or too cold, the weld may fail. Traditional heat guns can make it hard to control the exact temperature, but the Weldy HT1600 helps you avoid this problem. Still, you need to practice to get the best results. Lightweight fabrics can wrinkle or stick to themselves if you use too much air. Different coatings may need different heat settings. Always test your plastic welder on scrap material first.

You can use a soldering iron as a plastic welder for small repairs. This tool has a hot metal tip that melts plastic at the spot you touch. Many people like soldering irons because they are cheap and easy to find. You can fix toys, electronics, or small cracks with this plastic welder. You need to practice to make your repairs look neat. Soldering irons work best for tiny jobs, not for big or thick plastic. If you want a plastic welder for crafts or quick fixes, this tool is a good choice. You may find it hard to get strong, smooth welds on larger projects.

An extrusion welder is a powerful plastic welder for big jobs. This tool melts plastic rods and pushes the melted plastic out through a nozzle. You use it for welding thick plastic sheets, pipes, or tanks. This plastic welder makes strong and even welds. You see extrusion welders in factories or on construction sites. They work better than hot air welding guns when you need to join thick or heavy plastic. You need special training to use this plastic welder well. It is not the best choice for small repairs or home use.

Ultrasonic welders use sound waves to join plastic. This plastic welder vibrates at a high frequency, making heat that melts the plastic at the joint. You do not need glue or extra rods. Ultrasonic welders work very fast and make clean, precise welds. You find this plastic welder in factories that make electronics, medical devices, or car parts. It works best for small parts and thin plastic. The machine costs a lot, so you usually see it in big companies. If you need high precision, this plastic welder is a top pick.

A chemical welder uses special liquids to bond plastic. You apply the liquid to the surfaces you want to join. The plastic melts a little and sticks together. This plastic welder is good for crafts, models, or quick repairs. You do not need heat or special skills. Chemical welders work best for small jobs and thin plastic. They do not make welds as strong as other plastic welders. If you want a simple plastic welder for light work, this tool is easy to use.

Tip: Each plastic welder has its own strengths. Pick the one that matches your project size and needs.

Here is a table to help you compare the main pros and cons:

| Welding Method | Pros | Cons |

|---|---|---|

| Soldering Iron | Low cost, easy to use, good for small repairs | Needs practice for neat results, not for large projects |

| Ultrasonic Welder | Fast, precise, no extra materials needed | High cost, only for small parts |

| Extrusion Welder | Strong, uniform welds for thick plastic | Needs training, not for small jobs |

| Chemical Welder | Simple, no heat needed, good for quick fixes | Weaker bonds, best for thin plastic |

You will find that alternative plastic welders can outperform hot air welding guns in some cases:

Ultrasonic welders give you high precision for electronics and medical devices.

Extrusion welders make stronger welds for pipelines and heavy-duty plastic.

Chemical welders offer quick and easy fixes for crafts and models.

If you want a plastic welder for big, strong, or very precise jobs, you may choose one of these tools. For most repairs and general use, a hot air welding gun gives you the best mix of control and flexibility.

You want your plastic welder to work fast and save time. Different tools have different speeds. Here is a table to help you see how each method compares:

| Welding Method | Speed Characteristics |

|---|---|

| Freehand Hot Air | Slower than most other welding methods; versatile but time-consuming. |

| Speed Tip Welding | Faster than freehand hot air welding; can be used in tight corners; still generally slower than extrusion welding. |

| Extrusion Welding | Allows larger welds in a single pass; preferred for thicker materials; faster than hot air welding methods. |

| Ultrasonic Welding | Rapid and precise joining; faster than hot air welding; uses high-frequency vibrations to generate heat quickly. |

| Chemical Welding | No explicit speed comparison available. |

You will notice that ultrasonic welding joins plastics very quickly. Extrusion welding also works fast, especially for thick materials. A hot air welding gun, like the Weldy HT1600, gives you steady results but takes more time than ultrasonic or extrusion welders. You can use speed tip welding to go faster, but it still does not match the speed of extrusion or ultrasonic methods. If you want a balance between speed and control, a hot air welding gun is a solid choice for many jobs.

You need strong welds for your projects to last. Extrusion welders make the strongest bonds, especially for thick plastic. Ultrasonic welders create tight, clean joints for small parts. A hot air welding gun gives you reliable welds on many types of plastic. The Weldy HT1600 stands out because it reaches high temperatures and keeps the heat steady. This helps you get even, strong welds if you prepare your surfaces well. Soldering irons and chemical welders work best for small or light-duty repairs. They do not match the strength of a hot air welding gun or extrusion welder.

Tip: Always match your welding method to the thickness and type of plastic. This helps you get the best weld strength.

You want a plastic welder that is easy to handle. Hot air welding guns have a learning curve, but you can master them with practice. You need to learn how to set the temperature, pick the right nozzle, and move at the right speed. The Weldy HT1600 makes this easier with its ergonomic handle and simple controls. You can adjust the heat gun to fit your project. Beginners often make mistakes like overheating or moving too fast, but you can avoid these with practice.

You will find that hot air welding guns are flexible and beginner-friendly.

Soldering irons are simple for small jobs but do not work well for big repairs.

Extrusion welders need more training and skill.

Ultrasonic welders require special machines and are not common for home use.

Chemical welders are easy for quick fixes but do not give you strong or neat results.

You can start with a hot air welding gun and improve your skills over time. The Weldy HT1600 helps you work longer without hand fatigue because of its ergonomic design.

You must think about safety when you use any plastic welder. Hot air welding guns and heat guns get very hot. You should wear gloves and eye protection. The Weldy HT1600 has a dustproof design and meets safety standards, which helps protect you during long jobs. Soldering irons also get hot and can burn you if you touch the tip. Extrusion welders and ultrasonic welders need special care because they use high heat or sound waves. Chemical welders use strong liquids, so you should work in a well-ventilated area and avoid skin contact.

Note: Always read the manual and follow safety tips for your plastic welder. This keeps you safe and helps your projects turn out better.

You should always match your plastic welding tool to your project. Each tool works best for certain jobs. Here are some common project types and the tools that fit them:

Hot air welding guns work well for plastic fabrication, fabric repair, automotive bin repair, flooring, and T-lock vinyl flooring. You can use them for many shapes and sizes because you can adjust the temperature and airflow. These tools let you control the weld by hand, which helps with repairs and custom work.

Extrusion welders handle thick plastic parts, such as tanks, pipes, or large containers. You get strong, even welds on heavy-duty projects.

Ultrasonic welders suit small, precise parts. You find them in electronics, medical devices, and car parts. They work fast and make clean joints.

Chemical welders are best for crafts, models, or quick fixes. You do not need heat, so they are good for thin plastics and simple repairs.

Soldering irons help with tiny cracks, toys, or electronics. They are easy to use for small jobs.

Tip: If you need flexibility and manual control, choose a hot air welding gun. For thick or large parts, pick an extrusion welder. For speed and precision, ultrasonic welders are best.

Your experience matters when you pick a plastic welding tool. Some tools are easier to learn than others.

Beginners often start with hot air welding guns or soldering irons. Hot air welding guns like the Weldy HT1600 offer adjustable settings and ergonomic handles, making them friendly for new users. You can practice on scrap material to build your skills.

Hobbyists may enjoy chemical welders for crafts or small repairs. These tools do not need much training.

Professionals use extrusion welders or ultrasonic welders for advanced projects. These tools require special training and experience.

Here are some steps to help you get started:

Clean and sand the surfaces before welding.

Identify the plastic type using recycling codes.

Wear safety gear like goggles and gloves.

Set the correct temperature for your plastic.

Test your tool on scrap material first.

Hold the tool at a 45-degree angle and move steadily.

Let the weld cool before checking its strength.

Fix common problems by adjusting temperature or cleaning surfaces.

Use matching welding rods for your plastic.

Start with simple projects and move to harder ones as you learn.

Note: Many manufacturers offer free training and support. Take advantage of these resources to improve your skills.

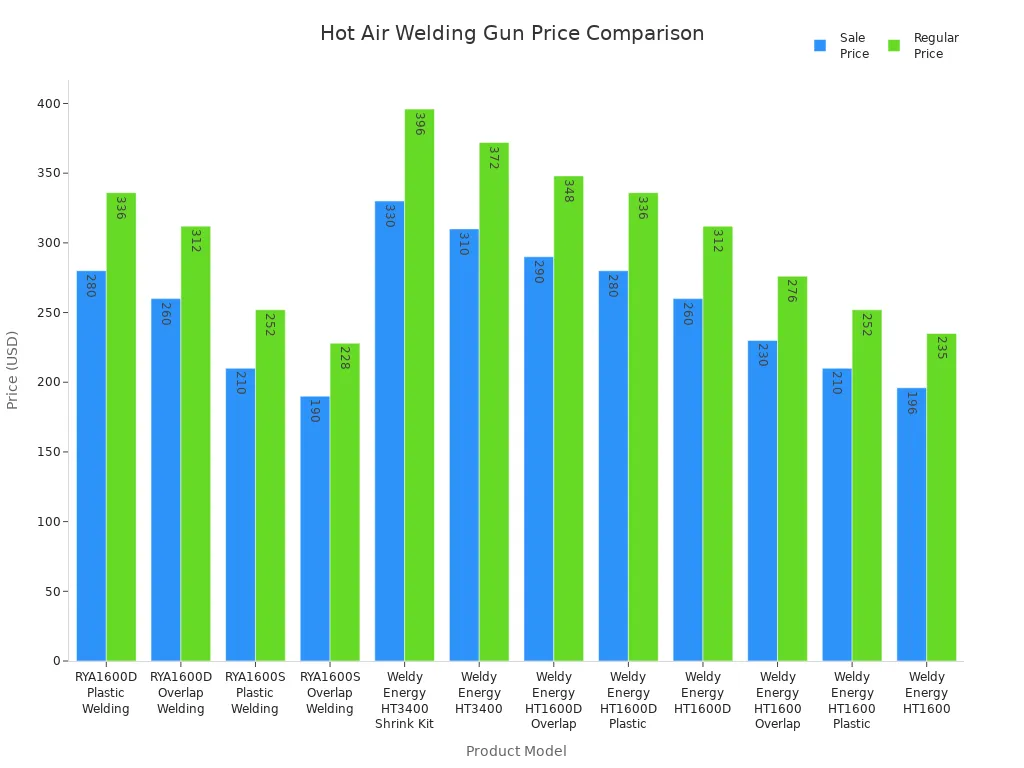

You should consider your budget before buying a plastic welding tool. Prices vary based on features and brand. Hot air welding guns offer a good balance between cost and performance. You can find models like the Weldy HT1600 for around $196 to $235. Other tools, such as extrusion or ultrasonic welders, cost much more and are usually for professional use.

Plastic welding kits bundle guns, rods, and accessories. These kits help beginners get started without buying each part separately. You can see the price range for hot air welding guns in the table below:

| Product Model | Sale Price (USD) | Regular Price (USD) |

|---|---|---|

| Weldy Energy HT1600 | 196 | 235 |

| Weldy Energy HT1600 Plastic Welding | 210 | 252 |

| Weldy Energy HT1600 Overlap Welding | 230 | 276 |

| Weldy Energy HT1600D | 260 | 312 |

| Weldy Energy HT1600D Plastic Welding | 280 | 336 |

| Weldy Energy HT1600D Overlap Welding | 290 | 348 |

| Weldy Energy HT3400 | 310 | 372 |

| Weldy Energy HT3400 Shrink Kit | 330 | 396 |

Tip: If you want a tool for many projects and repairs, a hot air welding gun gives you great value for your money.

You can use this table to compare the main types of plastic welding tools. It shows how each tool works, what jobs it fits, and what makes it different.

| Welding Method | How It Works | Best For | Key Differences | Price Range (USD) |

|---|---|---|---|---|

| Hot Air Welding Gun | Blows hot air to soften plastic and rod | Repairs, fabrication, flooring | Manual control, flexible, versatile | 196–330 |

| Soldering Iron | Heats a metal tip to melt plastic | Small repairs, electronics | Simple, low cost, less strong welds | 10–50 |

| Extrusion Welder | Melts and extrudes plastic rod onto joint | Thick plastic, tanks, pipes | Strong welds, needs training | 800+ |

| Ultrasonic Welder | Uses sound waves to melt joint | Small, precise parts, factories | Fast, clean, high cost | 2,000+ |

| Chemical Welder | Uses liquid solvent to bond plastics | Crafts, models, quick fixes | No heat, weaker bonds | 5–40 |

Note: Hot air welding guns give you the best mix of control, cost, and flexibility for most repair and fabrication jobs.

Practical Advice for Every User:

Beginners: Start with a hot air welding gun or a kit. Practice on scrap plastic. Learn to set the right temperature and use matching rods.

Hobbyists: Try chemical welders for crafts or soldering irons for small repairs. Move to hot air welding guns as you gain confidence.

Professionals: Choose the Weldy HT1600 for demanding jobs. Use extrusion or ultrasonic welders for thick or complex parts.

Remember, the right tool depends on your project, skill, and budget. Take your time to practice and learn. You will get better results and enjoy your work more.

You can choose the best plastic welding tool by thinking about your project, skill, and budget. Hot air welding guns, like the Weldy HT1600, give you power, control, and comfort for tough jobs. Industry experts say these tools work well for many tasks, from flooring to manufacturing. Start by listing your project needs and skill level. Try practicing on scrap plastic. You can talk to specialists or check reviews before you buy. With the right tool and a little practice, you will get strong, neat welds every time!

You can weld most thermoplastics, such as PVC, PE, PP, and ABS. Always check the recycling code on your material. Use a matching welding rod for the best results.

Test your weld by gently bending or pulling the joint after it cools. A strong weld will not break or crack. If it fails, try cleaning the surfaces and adjusting the temperature.

You do not need formal training. You can learn by practicing on scrap plastic. Start with simple projects. Many manufacturers offer guides and videos to help you improve your skills.

Yes! You can fix car bumpers, panels, and other plastic parts with a hot air welding gun. Clean the area first. Use the right rod and temperature for your plastic type.

Always wear gloves and safety glasses. Work in a well-ventilated area. Avoid touching the hot nozzle. Keep flammable items away from your workspace.