Views: 0 Author: Ruby Publish Time: 2026-02-18 Origin: Site

In butt fusion welding, the role of the facer is very clear: it prepares both pipe ends properly before welding.

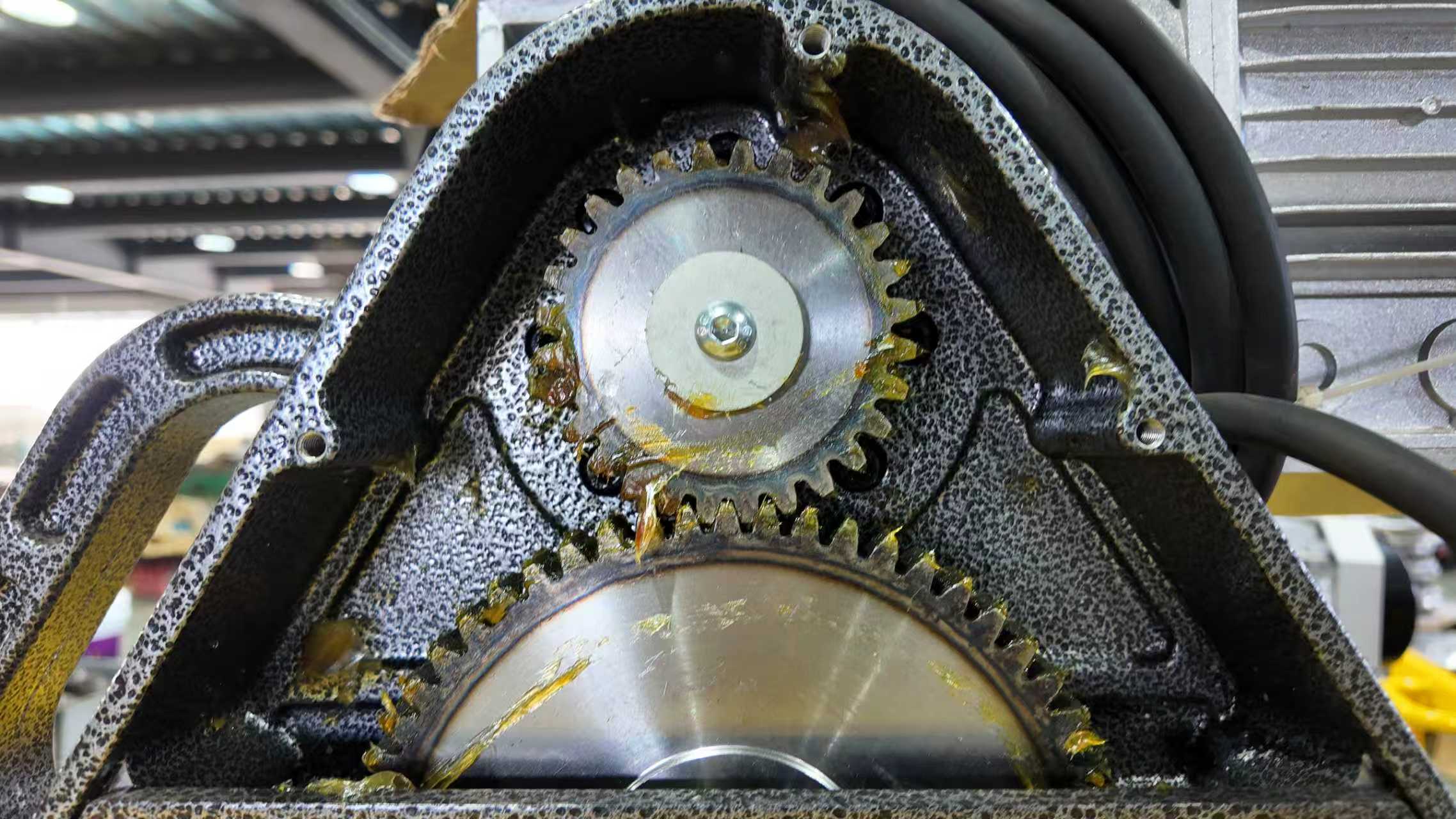

What really affects performance and long-term reliability is not the appearance, but the internal drive structure.

All of our facers use a gear-driven internal structure.

There is no chain transmission inside.

With direct gear engagement, the contact area between components is larger, which results in higher transmission efficiency and smoother rotation. The drive remains stable even after long periods of use.

Compared with common chain-driven facers on the market, a gear drive offers clear practical advantages:

·No risk of chain loosening or chain drop

·Less vibration after extended use

·Easier maintenance, without frequent adjustment

This structure is a key reason why the overall facer performance stays consistent over time.

Simultaneous Facing on Both Pipe Ends

Once the facer is started, the internal gear system drives the cutter plates smoothly, allowing both pipe ends to be faced at the same time.

This synchronized facing helps ensure flatness and consistency on both ends, reducing alignment issues and unnecessary rework before welding.

The result is a more efficient and predictable preparation process.

In real jobsite conditions, a facer is not used occasionally—it works continuously.

Stable rotation and even cutting are what matter most in daily operation.

A gear-driven facer delivers exactly that: steady performance, controlled cutting, and reliability that holds up over time.

This is where the value of the internal structure is truly felt.