Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

Fusion pipe welding uses heat and pressure to join plastic pipes. This makes a strong and smooth connection. People use this method for home repairs and water lines. It is also used in big projects. Beginners and DIYers like it because it is simple and safe. Special machines like the WELPING WP355A make fusion pipe welding easier.

The WP355A makes pipe welding faster and joints stronger. It also helps cut down on waste.

Benefit Result Weld Integrity Rate 99.8% Installation Speed 50% faster Operational Cost Savings 60% lower than older methods

Fusion pipe welding is a good choice for many common jobs.

Fusion pipe welding connects plastic pipes by heating and pressing their ends together. This makes strong joints that do not leak and last many years.

Using good machines like the WELPING WP355A gives steady heat and pressure. This helps make welding quicker, safer, and more dependable for new and skilled workers.

Getting ready the right way is important. You need to cut, clean, and line up the pipe ends. This helps make strong joints and stops mistakes that can cause leaks.

Safety gear like gloves, goggles, and special clothes keeps workers safe during welding. Following safety rules lowers accidents and makes work better.

Fusion pipe welding is good for plumbing, gas, water lines, irrigation, and factories. It helps save water, lower costs, and keeps systems working well.

Fusion pipe welding joins two pieces of plastic pipe by heating their ends and pressing them together. This process creates a single, strong joint that looks and acts like one continuous pipe. Workers use this method for many types of plastic pipes, such as HDPE and PE. The process uses special machines to heat and align the pipes. These machines help keep the pipes steady and make sure the joint is even.

Pipe fusion works by melting the ends of the pipes until they become soft. Then, the operator pushes the ends together with steady pressure. The melted plastic mixes and cools, forming a solid bond. This method does not need glue or extra materials. The joint becomes as strong as the pipe itself.

Technical studies show that the fusion line, weld metal, and heat-affected zone each have different properties. The table below shows some important measurements from these areas:

| Parameter | Fusion Line (FL) | Weld Metal (WM) | Heat-Affected Zone (HAZ) |

|---|---|---|---|

| Vicker’s Hardness (HV0.05) | ~156 | ~165 | ~176 |

| Young’s Modulus (GPa, Indent) | ~184 | ~193 | ~198 |

| Young’s Modulus (GPa, EBSD) | ~189-191 | ~194-202 | ~192-214 |

| Average Schmid Factor | 0.476 (highest) | 0.466 | 0.467 |

These numbers help explain why pipe fusion joints are strong and reliable. The fusion boundary has a special structure that helps the joint resist cracks and leaks.

Pipe fusion offers many advantages for both professionals and beginners. Here are some key benefits:

Strong, Seamless Joints

Pipe fusion creates joints that are as strong as the pipe itself. The joint does not have weak spots or seams that can leak.

Long-Lasting Connections

The process forms a bond that lasts for many years. This makes it a good choice for water, gas, and industrial lines.

No Extra Materials Needed

Fusion pipe welding does not use glue, solvents, or other chemicals. The process only uses heat and pressure.

Safe and Clean

The method does not release fumes or leave behind sticky residue. Workers can use pipe fusion in homes, schools, and outdoor settings.

Versatile Applications

People use fusion pipe welding for plumbing, irrigation, and even large municipal projects. The same process works for many pipe sizes and types.

Tip: Using a high-quality fusion machine helps ensure every joint is strong and safe. Machines like the WELPING WP355A provide steady heat and pressure for the best results.

Pipe fusion also helps reduce waste. Workers can cut pipes to the exact length needed and join them on-site. This saves time and money. The process also supports clean water and gas delivery by preventing leaks.

Getting ready is important for a strong pipe fusion joint. First, workers measure and cut the pipes to the right length. They use a pipe cutter or saw for straight cuts. Next, they clean the pipe ends to remove dirt or grease. Clean ends help the melted plastic stick together well. Operators use a planing tool, called a facer, to shave the pipe ends. This makes both ends flat and smooth. The pipes must line up perfectly in the fusion machine. If the pipes are not lined up, the joint can be weak. Workers clamp the pipes tightly in the machine’s carriage. This keeps the pipes still for the next steps.

Full factorial design of experiments helps find the best force and heating time for each job.

Mathematical models connect input settings to temperature and melted plastic thickness.

Infrared imaging checks the temperature at the pipe ends.

Measurements show how heat moves during each step.

The melted zone’s thickness is important for a strong weld.

Thermal analysis shows how the pipe changes during fusion.

These methods help with preparation, heating, joining, and cooling.

Tip: Always look at the pipe ends for cracks or defects before you start. Even small problems can make the joint weak.

Heating and joining is the main part of pipe fusion. Workers put a special heater plate between the pipe ends. The heater warms both ends until the plastic gets soft and starts to melt. The temperature must be even across the surface. If the heat is not even, weak spots can form. When the pipe ends are hot enough, the operator takes away the heater. The pipes move together quickly with steady pressure. The melted plastic mixes at the joint. This makes one smooth connection. The operator holds the pressure for a set time. This lets the plastic fuse all the way.

Researchers use infrared cameras to watch the temperature during this step. They also check the melted plastic’s thickness. These checks help make sure the joint is strong and does not leak. The right heat and pressure are very important for a good joint.

Cooling is the last step in pipe fusion. After joining, the operator keeps the pipes clamped together. The plastic cools and gets hard. This step takes longer for thick pipes. The joint gets stronger as the plastic cools down. Studies show cooling time depends on pipe wall thickness and temperature. Old ways, like using ice water, do not make cooling much faster because plastic keeps heat in. New formulas help workers know the shortest safe cooling time. This lets them handle the pipes sooner without making the joint weak.

Tests on butt-fused joints show cooling is important for long-lasting joints. The joint must cool enough to stay strong over time. If cooling is rushed, the middle of the joint can be weak. Careful cooling helps stop leaks or breaks later.

Note: Never take the pipe out of the clamps before cooling is done. If you rush this step, the joint can be ruined.

You need the right tools for hdpe pipe fusion. The main tool is a hydraulic butt fusion welding machine. The WELPING WP355A is good for many jobs. It works with pipes from 160mm to 355mm. You can use reducers for smaller pipes. The machine has a carriage to line up pipes. A planing tool trims the pipe ends. The heater warms the pipes evenly. The hydraulic station controls the pressure for welding.

| Specification | Details |

|---|---|

| Welding Range (mm) | 160-355 (optional 90-140) |

| Power Supply | 220V/50Hz, single phase (380V optional) |

| Max Heating Plate Temp | 270ºC |

| Temperature Deviation | ±5ºC |

| Total Power Consumption | 5.45 KW |

| Pressure Adjusting Range | 0-8 MPa |

The WP355A uses four jaw clamps to hold pipes straight. Its hydraulic cylinders and steel parts make it strong. Thermocouple sensors help keep the heat steady. The heater has a Teflon coating. The frame covers the machine to block dust and sand. These features help make strong pipe joints.

Good pipe fusion equipment helps stop mistakes. It keeps welds the same every time. The controls and alignment help stop leaks. Many companies use the WP355A for hdpe pipe fusion.

Safety is very important when using pipe fusion tools. Workers should wear gloves that resist heat. They also need safety goggles and special clothes. Insulated boots keep feet safe from hot parts. The WP355A has a switch to stop electric leaks. It also has a safe plug for power. These things help stop accidents.

Tip: Always check your safety gear before you start. The right gear and setup keep you and the pipe safe.

Fusion pipe welding lets plumbers make strong joints that do not leak. HDPE and PE pipes joined this way do not rust and last a long time. Many plumbers use fusion welding for new water pipes and fixing old ones. This method works in small houses and big buildings. Fusion joints do not need glue or extra parts, so leaks are less likely. Water stays clean because the pipes do not mix with chemicals.

HDPE pipes joined by fusion welding are used in homes and businesses.

Joints that do not leak help stop water waste and save money.

Good pipe alignment and the right heat make strong joints.

Cities use fusion pipe welding for gas and water pipes. Workers put HDPE pipes underground to keep them safe and strong. These pipes can handle high pressure and bad weather. Fusion joints stay strong for many years. City water systems use this method to stop service problems. Gas companies like fusion welding because it seals the pipes tight.

| Application Area | Key Benefit | Typical Setting |

|---|---|---|

| Water Pipeline Systems | Leak-proof, long lifespan | Municipal, rural, urban |

| Gas Pipeline Systems | Safe, corrosion-resistant | Cities, industry |

Farmers and gardeners use fusion pipe welding for watering systems. HDPE pipes move water to plants without leaking. Fusion joints help save water and money and keep plants healthy. In the country, fusion-welded pipes have stopped water system breaks by 20%. HDPE pipes bend easily, so they fit around fields and things in the way.

Irrigation systems use strong, bendy pipes.

Fusion welding helps bring water fast during dry times.

Industries like mining, landfills, and farming use fusion pipe welding. HDPE pipes move chemicals, waste, and water in hard places. Fusion makes joints that can handle strong chemicals and heavy things. Many factories use this method to keep working without problems. The WELPING WP355A machine helps workers make good joints for big jobs.

Fusion pipe welding is used in many jobs because it is strong, flexible, and does not leak. This method helps move water, gas, and chemicals safely in homes and factories.

Safety is the most important thing in fusion pipe welding. Beginners should wear gloves, goggles, and protective clothes. The work area should be clean and not messy. Before starting, workers must check all tools for damage or loose parts. Cleaning heater plates and clamps often helps stop accidents. Training and working together help keep everyone safe. Welders with experience say to talk openly and follow safety rules every time.

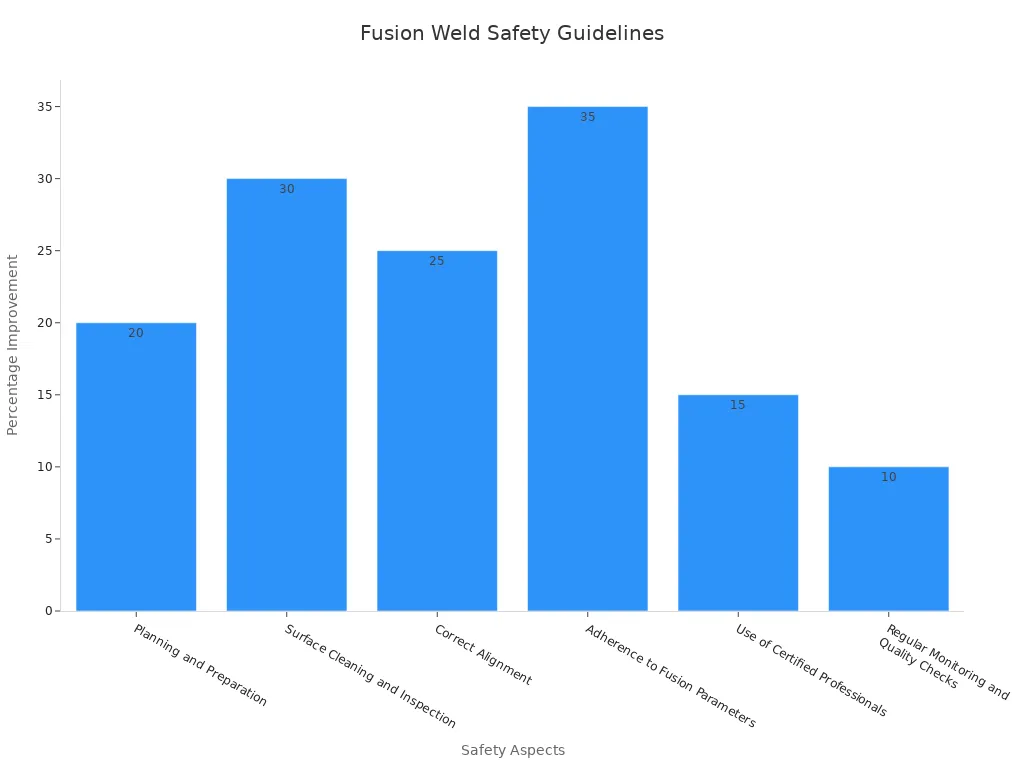

| Aspect | Description |

|---|---|

| Planning and Preparation | Do site checks, gather tools, make safety plans, and train the team. Well-prepared sites have fewer mistakes and finish faster by about 20%. |

| Surface Cleaning and Inspection | Clean and check pipe surfaces to get rid of dirt, water, and other stuff before fusion. Clean pipes lower the chance of joint failure by about 30%. |

| Equipment Maintenance | Clean and check heater plates, clamps, and controls often. Good care keeps welds strong and safe. |

Good joints start with careful work. Workers need to clean and check pipe ends before welding. Lining up pipes the right way makes joints up to 25% stronger. Using the machine’s settings for heat, pressure, and time helps stop weak spots. Checking the joint during and after welding helps make it better. Certified welders often get great results, but beginners can do well by following steps closely. Practicing often helps you get better at pipe fusion.

Tip: Let the joint cool all the way before taking it out of the clamps. If you hurry, the weld can get weak.

Many beginners make the same mistakes. They forget to check the machine, do not clean pipe ends, or line up pipes wrong. Some take the pipe out of the clamps too early, which makes weak joints. Others do not use the right heat or pressure settings. These mistakes can cause leaks or expensive fixes. Watching each step and using good methods helps stop these problems. Being careful at every step makes a safe and strong weld.

Fusion pipe welding makes joints that do not leak. These joints are strong for many kinds of jobs. The WELPING WP355A makes welding simple and dependable. Special machines keep the heat just right. This stops joints from breaking or leaking. The table below shows how good fusion welding helps:

| Metric | Result |

|---|---|

| Weld Integrity Rate | 99.8% |

| Water Loss Reduction | >15% annual cut |

| Maintenance Cost Reduction | 30% |

Anyone can get good results by being safe and using the right tools. You can find more tips at trade schools or on the internet. These places have guides that help you learn more.

The WELPING WP355A works best with HDPE and PE pipes. These materials melt and fuse well. The machine handles pipe sizes from 160mm to 355mm. Optional reducers allow use with smaller pipes.

Cooling time depends on pipe thickness. Most joints need 10 to 20 minutes to cool fully. Thicker pipes may need more time. Always wait until the joint feels cool before removing clamps.

Fusion pipe welding is safe when users follow safety rules. Gloves, goggles, and protective clothing help prevent burns. The WP355A includes safety features like an electricity leakage protection switch.

Beginners can use the WP355A with basic training. The machine’s controls are simple. Clear instructions guide users through each step. Practice helps improve results.

Users should inspect the joint for cracks or misalignment. If a leak appears, cut out the faulty section and repeat the fusion process. Proper cleaning and alignment help prevent leaks.