Views: 0 Author: Site Editor Publish Time: 2025-07-21 Origin: Site

Choosing between an electro fusion welding machine and a butt fusion welding machine depends on your project requirements. Consider factors like pipe size, site conditions, and overall cost. An electro fusion welding machine is often the best choice for smaller pipes, repairs, or complex fitting jobs. Butt fusion welding works well for joining larger pipes, especially in extensive projects. Many industry professionals recognize that an electro fusion welding machine delivers excellent results in tight spaces or when connecting different pipe materials. Recent advancements in construction show that both welding methods now incorporate smarter controls and improved welding settings, enhancing the quality of pipe networks.

Pick electrofusion welding for small pipes and repairs. It works well in tight spaces. This method is good when you need control and easy moving.

Use butt fusion welding for big pipes and large jobs. It is best for fast, strong, and cheap pipe joints.

Think about pipe size and the work area before you choose. Also, look at your budget, skills, and if you have enough power.

New welding machines have smart controls and track data. These features help make better welds and fewer mistakes. They also help save time.

Get good training and follow each step closely. This keeps pipe joints safe, strong, and lasting a long time with any method.

When you look at electrofusion and butt fusion welding, you find some big differences. Each way of joining pipes has its own good points for building projects. Here are the main things to think about:

Electrofusion uses special tools with heating parts inside. Butt fusion welding uses hot plates and clamps to join pipes.

Electrofusion can join pipes that are not the same size or material. Butt welding works best when pipes are the same size and made from the same stuff.

Electrofusion lets you control the welding process very closely. Butt fusion welding is easier to use and usually costs less.

Electrofusion is great for tricky repairs and tight spots. Butt welding is better for putting in big pipes on large jobs.

Electrofusion costs more at first and needs trained workers. Butt fusion welding tools cost less, but you still need skilled people.

Both ways make strong pipe joints if a licensed welder does the job. You get safe and fast results with either method if you follow the rules.

Tip: Electrofusion is usually better for fixing pipes or working in small spaces. Butt fusion welding is best for big building jobs where saving money and time is important.

The table below shows how each fusion method works for different needs. New research says pipe size, wall thickness, and cost savings are not the same for both. This helps you pick the right way to join pipes for your project.

| Welding Method | Pipe Size Limitations | Wall Thickness Limitations | Direct Cost Savings | Indirect Cost Savings |

|---|---|---|---|---|

| Electrofusion | Tubing NPS 5 (DN 125) or less | 1/2 in. (13 mm) or less | $100,000s (avoids PWHT) | Millions (less downtime, less damage) |

| Butt Fusion Welding | Large diameter, no strict limit | Up to pipe spec | High (lower equipment cost) | High (faster installation, reliability) |

You can see that butt fusion welding is good for bigger pipes and works fast on large projects. Electrofusion is best for smaller pipes and saves a lot of money on repairs and upkeep.

An electrofusion welding machine joins pipes by heating special fittings. These fittings have wires inside them. First, you must clean and scrape the pipe ends. Next, you line up the pipes inside the fitting. The machine sends electricity through the wires. This melts the pipes and fitting together. The melted parts cool and form a strong, leak-proof joint. New electrofusion machines, like the WELPING 20mm-200mm Industrial Level Portable Electrofusion Welding Machine, use smart microcontrollers for better control. Many machines have barcode scanners and record data as you work. They can also change welding settings automatically. These machines work with polyethylene, HDPE, and PP pipes. They are strong enough for tough jobs outside.

Electrofusion welding has many good points. You can use it in small spaces or for repairs. Other methods may not fit in these places. The process does not need much manual work. This lowers the chance of making mistakes. Electrofusion joints are strong and last a long time. They stay strong even after many tests. Some machines can log data and connect wirelessly. This helps you check every weld for quality. But, you must clean and line up the pipes well. If you do not, the joint may not be strong. Even so, electrofusion welding is a top pick for many jobs.

Note: New electrofusion machines have touch screens and can run on batteries. Their heating parts do not rust. These upgrades make the job faster and more reliable.

Pick electrofusion welding for small or medium pipes. It is great for tight spaces or tricky fittings. This method is good for repairs and joining pipes of different sizes. It is also best when you need strong, traceable joints. The WELPING electrofusion welding machine is easy to carry and has smart controls. This makes it good for work indoors or outside. Electrofusion is often used for city water and gas pipes made from polyethylene. As machines get better, electrofusion welding gives you more ways to finish your work well.

Butt welding joins two pipes by heating and pressing them. This works best for big polyethylene pipes. First, you clean the pipe ends to remove dirt. Then, you clamp the pipes in the machine to keep them straight. Next, you trim the ends with a tool so they are smooth. After that, you put a heating plate between the pipe ends. The plate heats the ends to the right temperature. When the ends are hot, you take out the plate. You press the pipes together and hold them until they cool. The joint gets hard and strong. Machines now help you watch heat and pressure. This makes the process more exact and helps stop mistakes. These steps make butt fusion joints that last a long time.

Butt fusion welding has many good points for projects. The joints are as strong as the pipe. This means they work well for water and sewage systems. The process is good for high-pressure jobs. Hydraulic and CNC machines make the work faster and more exact. This lowers labor costs and saves time. But, you must get the pipe ends ready and keep them clean. Skilled welders are needed to control heat and pressure. If you rush cooling or do not line up the pipes, the joint can be weak. The table below shows the main pros and cons:

| Aspect | Pros | Cons |

|---|---|---|

| Joint Strength | Butt fusion joints match pipe strength | Needs precise surface preparation |

| Installation Complexity | Good for high-pressure, large-diameter pipes | More complex than socket welding |

| Skill Level Required | High skill ensures strong, leak-free joints | Demands experienced welders |

| Corrosion Resistance | Excellent due to smooth, continuous welds | |

| Fatigue Strength | Handles pressure changes and vibration well | |

| Suitability | Ideal for big infrastructure projects | Longer installation times possible |

| Leakage Risk | Low if you follow proper steps | Requires strict quality control |

Tip: Always check butt fusion joints after welding. This makes sure they are safe.

Pick butt fusion welding for big projects that need strong pipes. It is great for water lines, sewage, and factory pipes. You can use it for pipes from 100 mm to 1200 mm wide or more. More places are buying butt welding machines as they build new things. New machines have smart controls and wireless data. Some even use AI to help with repairs. These features help you finish big jobs faster and with fewer mistakes. If you want strong, low-cost, and long-lasting pipe joints, butt fusion welding is the best choice for big polyethylene pipes.

Picking the best welding method takes some thought. You need to look at what your project needs. Each method has things it does well. Here is a simple guide to help you choose.

Pipe size is very important when picking a method. Electrofusion works best for pipes that are small, up to 200mm wide. Butt fusion welding is better for big pipes. It is good when you need to join long pipes in large jobs.

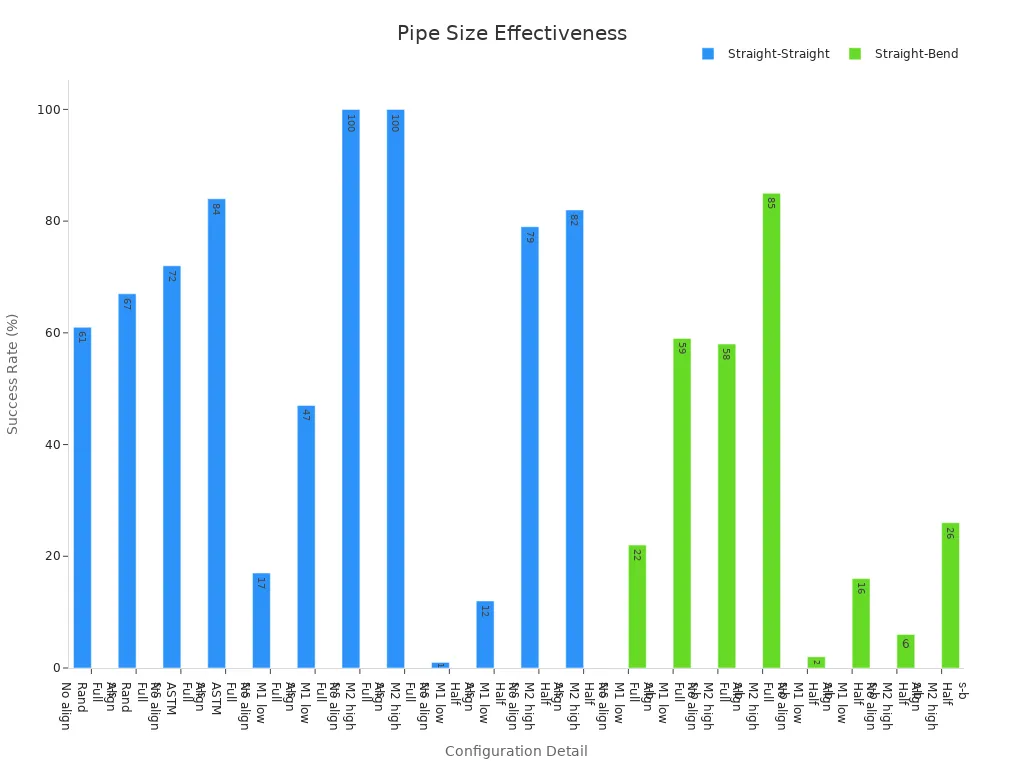

The table below shows how pipe alignment and wall thickness matter. If pipes are lined up right and made well, joints are stronger.

| Pipe Configuration | Wall Thickness | Manufacturer / Tolerance | Alignment | Success Rate (%) |

|---|---|---|---|---|

| Straight pipe to straight pipe (s–s) | Full (316L) | Manufacturer 2 (high tolerance) | Aligned | 100 |

| Straight pipe to straight pipe (s–s) | Full (316L) | Manufacturer 2 (high tolerance) | No alignment | 100 |

| Straight pipe to straight pipe (s–s) | Full (316L) | ASTM tolerances | Aligned | 84 |

| Straight pipe to straight pipe (s–s) | Full (316L) | ASTM tolerances | No alignment | 72 |

| Straight pipe to straight pipe (s–s) | Full (316L) | Manufacturer 1 (low tolerance) | Aligned | 47 |

| Straight pipe to straight pipe (s–s) | Full (316L) | Manufacturer 1 (low tolerance) | No alignment | 17 |

Tip: Use electrofusion for pipes under 200mm. It is flexible and makes strong joints. For pipes over 200mm, butt fusion welding is faster and more reliable.

Think about where you will do the welding. Electrofusion is great in small or tight places. It works well for repairs in cities or inside buildings. Machines like the WELPING 20mm-200mm Industrial Level Portable Electrofusion Welding Machine are easy to move and use.

Butt fusion welding needs more space for the tools and pipes. This method is best for open areas or big building sites. You need room to set up and work with bigger machines.

Note: If you work underground or in bad weather, electrofusion is easier to use. It saves time and lowers risk because it is portable.

How much money you have matters a lot. Electrofusion machines and parts cost more at first. You also need to pay for training your team. But this method can save money later by cutting down on repairs and lost time. Cleaning and getting ready can lower joint problems by 30%. Certified workers can cut down on rework by 15%.

Butt fusion welding machines cost less if you pick manual ones. Automatic machines cost more but save money over time. They work faster and need less work from people. The table below shows the differences:

| Feature | Manual Butt Fusion Machine | Automatic Butt Fusion Machine |

|---|---|---|

| Upfront Cost | Lower upfront cost, suitable for smaller projects | Higher upfront cost but offers long-term savings through increased productivity and reduced labor costs |

| Welding Throughput | 2-3 joints per hour | 3-4 joints per hour |

| Labor and Productivity | Operator-dependent, lower throughput | Highly automated, higher throughput |

Tip: Think about both direct and hidden costs. Good planning and checking your work can stop mistakes and save money.

Your team’s skills change how good the welds are. Electrofusion needs careful work and following steps. Operators must pay attention to details. Machines with smart controls, like the WELPING electrofusion welder, help new users. But training is still needed.

Butt fusion welding needs a lot of skill, especially for big pipes. Workers must control heat, pressure, and keep pipes straight. Skilled welders make fewer mistakes and better joints. Training and certificates help get better results.

Callout: Pick a method that fits your team’s skills. For hard or risky jobs, make sure your team is trained and certified.

Check what power you have at your site. Electrofusion machines can use normal outlets or portable generators. This makes them good for far away or indoor jobs.

Butt fusion welding machines, like hydraulic or automatic types, may need more power. Make sure your site can give enough power for these machines.

Tip: Always check power needs before you start. This helps you avoid delays.

| Factor | Electrofusion | Butt Fusion Welding |

|---|---|---|

| Pipe Size | Best for ≤ 200mm | Best for > 200mm |

| Site Conditions | Confined, indoor, or repair sites | Open, large-scale construction |

| Budget | Higher upfront, lower repair costs | Lower upfront, higher labor costs |

| Skill Level | Needs training, smart controls help | High skill, training essential |

| Power Source | Flexible, portable | Needs stable, higher power |

The best method depends on your project’s needs. Look at pipe size, site, budget, skills, and power before you decide.

Welding technology will change a lot in 2025. The market is growing because of new digital tools and smarter machines. Many companies now use automation, robots, and artificial intelligence. These things make welding safer and faster. More welding machines will have real-time monitoring and predictive maintenance. These features help you find problems early and keep machines working longer.

Market reports say digital tools like IoT sensors and machine learning are common in welding now.

Companies want eco-friendly welding and energy-saving machines.

Asia-Pacific, North America, and Europe are growing fast because of new buildings and clean energy projects.

Wires and electrodes are now made for digital welding and to help the environment.

The market for advanced welding, including electrofusion, is growing to help industries like electric cars and 3D printing.

Tip: Pick welding machines with smart controls and data tracking. These features help you get better quality and less downtime.

| Trend | Impact on Your Project |

|---|---|

| Automation & AI | More accuracy, fewer mistakes |

| Digital Connectivity | Watch in real time, easy to report |

| Sustainability Focus | Less pollution, saves energy |

| Customization Demand | Fits special jobs better |

You can get better welding results by using new methods. Experts say to use advanced ways like Response Surface Methodology and Particle Swarm Optimization. These help you set current, voltage, and gas flow for better welds. You will waste less and save energy.

Always check how welding settings work together. Small changes can make joints much stronger.

Use machines that let you record and check welding data. This helps you see patterns and fix problems fast.

Try new tools like Six Sigma or artificial neural networks to keep welding jobs running well.

For electrofusion, follow every step and use smart machines for the best welds.

Note: Knowing your equipment and using data will help you make strong, safe welds every time.

Both electrofusion and butt fusion welding have their own good points. You should pick the one that fits your pipe size, where you work, and how much money you have. Research shows that choosing the right welding way makes building better and safer. Many experts use special guides to help them pick the best welding for each job. To get the best results, ask suppliers or professionals for advice. You can also look at new machines like the WELPING electrofusion welding machine to help your work. Always check what your project needs before making a choice.

You can use electrofusion welding machines with PE, HDPE, and PP pipes. These machines make strong joints that do not leak. They are good for water, gas, and factory systems.

Butt fusion welding needs more room to set up and work. It is hard to use in small or crowded places. Electrofusion welding is better for fixing pipes in tight spots.

Always look at the weld to see if it looks even. Use the machine’s data recording if it has that feature. Many new machines, like WELPING, save welding data to help check quality.

You need to learn how to use both machines the right way. Electrofusion and butt fusion both have steps you must follow for safety. Many companies have training classes for your team.